Tissue Printing Specifications

File Format:

- Files can be accepted in Photoshop and Illustrator format.

- PDF’s must be unlocked, layered, and fully illustrator editable.

- Files can be submitted via FTP, Email, CD/DVD, or another electronic download.

Placed Images / Scans Linked Files:

- All placed or linked images must be provided and should be a minimum of 300ppi at the printed size. Do not embed images.

Fonts:

Please supply both outlined and live font versions of your illustrator file. If using postscript fonts make sure to include all printer and screen fonts. We have an extensive library of fonts but we do not have every font. Fonts must be Mac compatible. Missing fonts can delay the process.

Type & Text:

- Positive Type – Minimum of 5 point. ® and TM can be as small as 4.5 pt.

- Reverse Out Type – Minimum of 6 point.

- Multi-color Build Type – Minimum of 8 point.

Rules & Lines:

- Positive Rule – Minimum 0.4 point (0.006″)

- Reverse Out Rule – Minimum of 0.75 point (0.01″)

- Multi-color Build Rule – Minimum of 1.5 point (0.02″)

Trapping:

- Standard Tissue Packaging trapping is 0.02″

Keylines:

- Keylines may be required for registration reasons for example, text that is reversed out of CMYK builds.

- Small type under 15 pt: 1.0 pt stroke / 0.5 pt visible – allows for 0.0035″ trap

- Medium type 16 pt – 30 pt: 1.5 pt stroke / 0.75 pt visible – allows for 0.005″ trap

- Large type 31 pt and up: 2.0 pt stroke / 1.0 pt visible – allows for 0.007″ trap

Plate Breaks and Edge Hold Backs:

- All jobs using flat plates will require a minimum plate break of .01875″ (3/16″). If the plate break is very tight with sharp curves or long ‘fingers’ the job will likely require a seamless ITR cylinder.

- Color hold back – 0.005″

Repeats:

- For flat plate jobs we require scatterprint artwork to form a repeating pattern. Our standard procedure is to make minor adjustments during proofing to acheive an existing cylinder repeat. The adjustments may include minor changes to logo size, spacing and design rotation.

- All process color tissue must print using an 18.0″ cylinder repeat.

Screens:

White ink, metallic inks or flouescent inks are not suitable for designs with screening. Line art screens on tissue start at 65-lpi and go up to 100-lpi determined by total ink coverage, color and/or ink density. Process color artwork prints on tissue at 100- or 133-lpi.

Micro Dots:

DigitalTissuePaper.com tissue presses require registration microdots. A minimum of two 0.016″ dots will be added to the outside edges of the web. Jobs more than 30″ wide require an additional microdot at the center of the web. Depending on the type of job or number of colors Aplasticbag.com may require additional marks such as registration crosshairs, follow bars and tone scales.

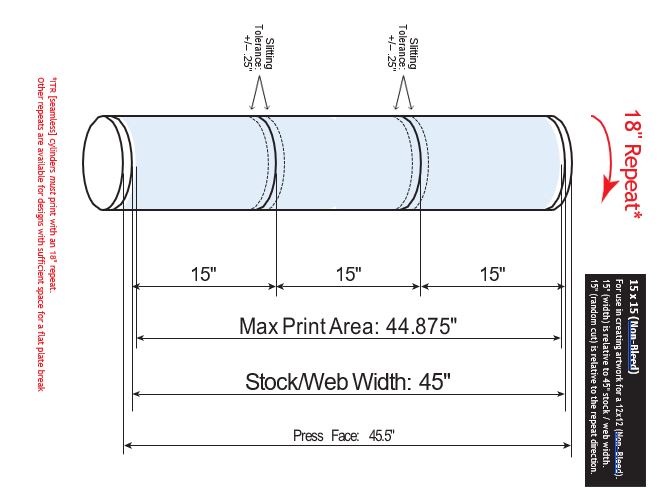

Unprinted Margins & Slitting Tolerances:

- Jobs without trim for bleed will be held back from the edges of the web by 0.0625″ (1/16″).

- DigitalTissuePaper.com has a +/– 0.25″ (1/4″) tolerance along the slit lines where a larger web is cut down to a smaller width prior to sheeting.

Colors:

Our tissue presses can print up to 6 colors.

Hard Copy Proofs (Color Targets):

If your design includes process colors please supply a color target. A color target is anything tangible that you are going to compare to our Contract Proof for process color approval.

Size / Scale:

- All artwork should be supplied at 100%.

- Stepped files and full sheets need to be clearly marked with information that shows us the intended orientation of the finished sheet.

Dielines & Sheet Size:

When supplying art for an impression job you must provide a dieline which shows proper placement of the eyemark(s). All art for sheeted (scatterprint) tissue should be supplied at 100% showing correct sheet size.

Scatterprint Designs:

- Scatterprint designs will be random cut. We can not control where scatterprint sheets cut.

- Supplied artwork should be set up in a repeating pattern or must be adjustable to achieve repeating pattern. Our most common repeats are 15.0″ 16.0″ 17.0″ and 18.0″.

Spot Sheeting:

- Spot sheeted jobs require 0.0375″ unprinted margins all around.

- Spot sheeted jobs require an eyespot. For jobs that print without trim the eyespot will show on the finished sheets.

UPC Rules & Regulations:

DigitalTissuePaper.com will only guarantee the scanability of UPC codes that meet the criteria listed below.

- Minimum UPC magnification is 80%

- If the bar code is less than 100% magnification, it must run in press direction.

- 100% bar codes require a “quiet zone” on both sides of 0.15″. This area must be free of any other art. (The quiet zone scales proportionately with the UPC magnifcation.)

- UPC bar codes must print in a color with reflectance value of 5% or less.

When Creating Artwork

It is important to understand the relationship between the finished product and the manner in which it will be produced.

DigitalTissuePaper.com prints roll to roll using central impression flexographic presses. Creation of all artwork should be built with this in mind.

While we are glad to provide assistance for any size, the following guidelines focus on common sizes used most at DigitalTissuePaper.com. Each is presented in terms of how it will be produced to provide a better understanding.

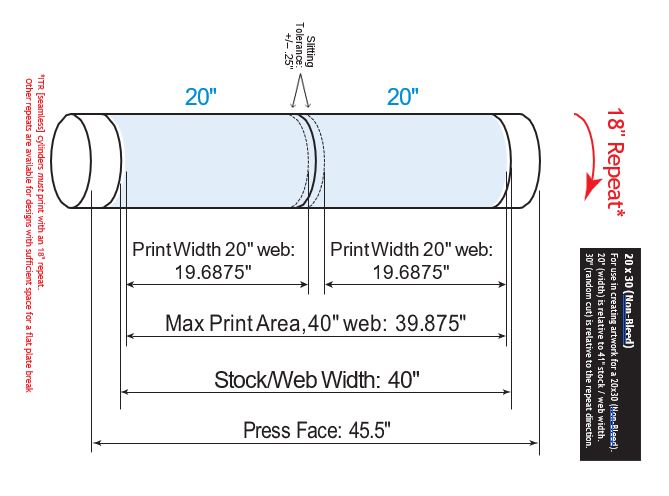

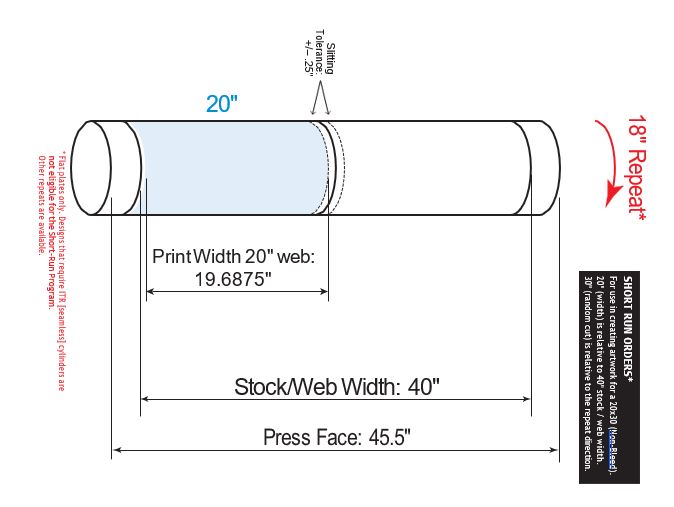

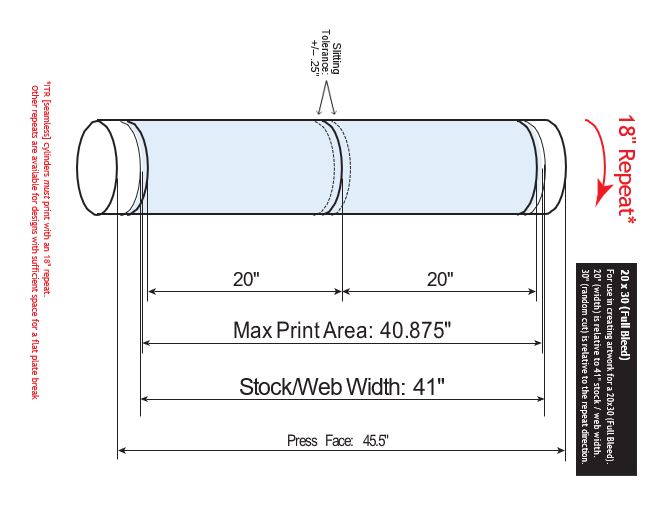

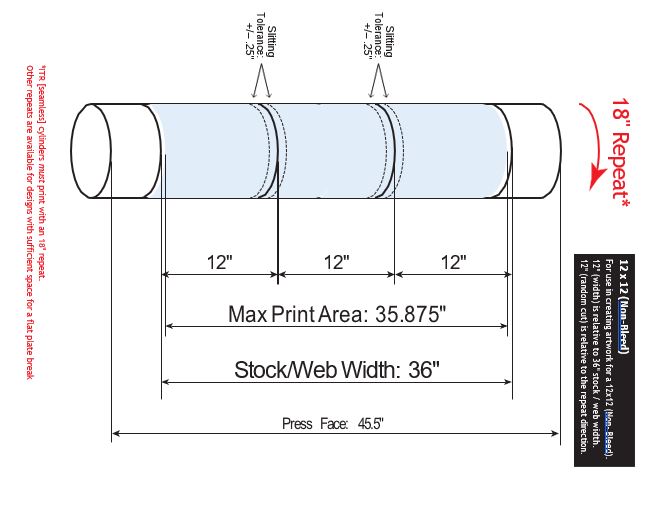

- Stock / Web Width indicates the width of the roll of paper on which your order will be printing.

- Max Print Area indicates the total width that the artwork should measure. This takes into consideration the Stock / Web width and the minimum 0.0625″ unprinted border or applicable bleed amount which must be included on either side of the printed web.

- Print Width indicates the total width in which we can control the layout of the finished sheets. This takes into consideration the slitting tolerance of the center trim.

- Repeat indicates the total length in which the artwork should repeat seamlessly to ensure the illusion of continuity on the finished product.

Regarding the following guidelines:

- These guidelines are for random sheeted product only.

- Continuous designs (such as stripes of tapestries) will require an ITR Cylinder. ITR cylinders are only available with an 18″ repeat. Please prepare artwork accordingly.

- To use a flat plate a minimum of 0.25″ space must be present between all design components.

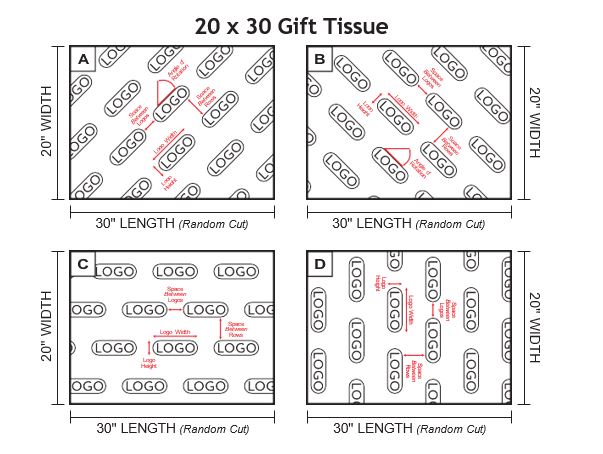

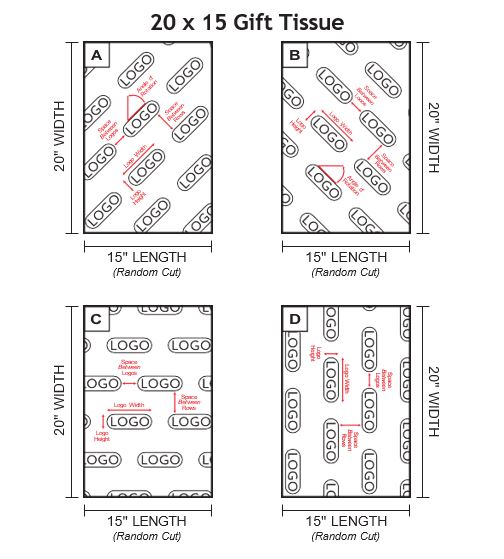

Gift Tissue Guidelines:

- 20 x 30 guidelines can for used for 20 x 15 (or any 20″ wide item.)

- Guidelines are provided for both standard orders (20+ reams) and our short run (10/12 ream) program in a non bleed format. Full bleed guidelines are also provided (applicable only to standard orders of 20 or more reams.)

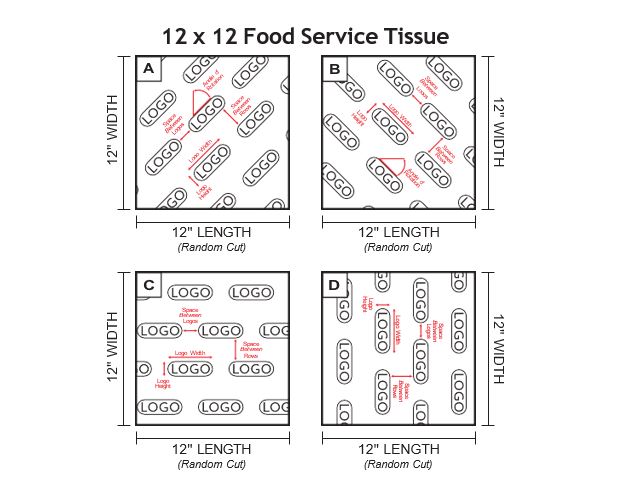

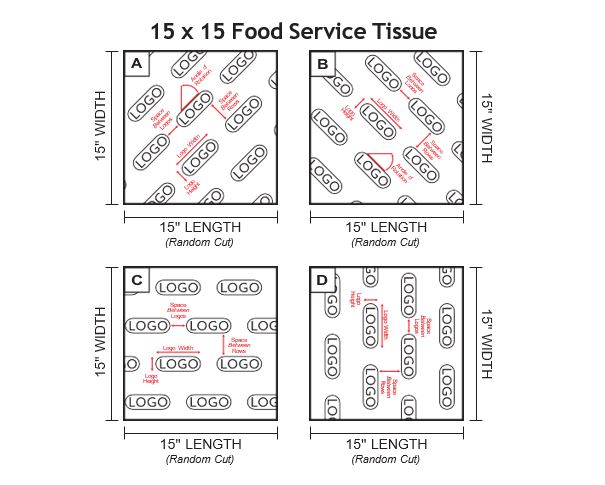

Food Tissue Guidelines:

- 12 x 12 guidelines can be used for any 12″ wide item just as 15 x 15 guidelines can for used for any 15″ wide item.

- Guidelines are provided in a non bleed format only. If a full bleed is required an adjustment to the sheet size may be necessary. Please contact your customer service representative for more information.

Information Required for Proofing (1-up) logo with Design Direction

To ensure our digital proof of your artwork is correct and meets your expectations, please provide the following information:

- Design Direction A, B, C or D

- Logo Size, Height or Width

- Spacing between logos [default is 1.0″]

- Spacing between rows of logos [default is 1.5″]

- Angle of rotation, for direction ‘A’ or ‘B’, if other than 45° [default].

Spot Sheeting

DigitalTissuePaper.com offers consistent design placement (unlike random sheets) better known as Spot Sheeting. Spot Sheet designs have special design considerations. Please see the information below.

Finished Sheet Width

Minimum 12″

Maximum 40″

Finished Sheet Length

Minimum 12″

Maximum 30″

- When creating artwork please remember the repeat dimension must measure the same as the finished sheet length.

- Repeat / Length must fit one of our existing cylinder repeats. Any artwork that does not fit an existing cylinder repeat will require adjustments.

- Spot sheet designs require a 0.375″ (3/8″) minimum unprinted border, all around, and eyespots on both edges of the web

- Removal of unprinted border or eyemarks may require offline cutting at an additional cost and reduction to sheet size.

- Artwork for Spot Sheet projects must be reviewed by our graphics and production teams to ensure they can be produced as requested. Any and all pricing is subject to review of final artwork and adjustments may be required

- 4/color process and multi-color line art require approval from our production team prior to acceptance of artwork and order.

- We reserve the right to decline any spot sheet project, at the discretion of our graphics and production teams.